After-Sales Service Services Procedures

Customer Feedback Efficiency

Supply-chain Sustainability Safety Challenge Prevention

Perception Measurable Conformity Total Satisfaction

Action plan Self-monitoring Management Training Sustainable

Customer Loyalty Monitoring Adaptation

QUALITY CONTROL

We

strive on a daily basis to ensure our customers’ total

satisfaction. We do our utmost to offer customised, innovative

solutions which meet their expectations. We have consequently adopted

a signage management quality (SMQ) approach and introduced strict

controls at all stages of the manufacturing process.

|

INTERNAL & EXTERNAL AUDITS

We

carry out regular internal & external quality audits of our

production sites and products. We also audit our methods &

procedures in order to ensure high quality standards as expected by

our customers. |

|

Oeko-tex Oeko-tex

Standard is a world-famous testing and certification system for

textile raw materials, intermediate and end products at all stages of

production. It excludes or strictly regulates, through laboratory

testing, the use of substances potentially harmful to health.

All our products are Oeko-Tex Standard 100 – class 1 certified. showing that our products have undergone rigorous testing and have complied with Oeko-Tex’s test criteria. A catalogue of criteria, comprising more than 100 different parameters, provides a scientifically sound basis for evaluating harmful substances, and is regularly updated in line with the latest regulations and clearly exceeds current legislation.  Oeko-tex

offers an additional level of quality control for INCH products, and

guarantees the safety and reliability of our products for the

consumer. Oeko-tex

offers an additional level of quality control for INCH products, and

guarantees the safety and reliability of our products for the

consumer. |

|

|

LABORATORY TESTS

Our

two laboratories, working in partnership with Sioen Industries (a

world leader in coating) conduct tests and inspections of materials

and finished products, to ensure that they meet performance, quality

and safety criteria: wash, waterproofing, breathability, durability,

tear resistance tests, etc., in accordance with current standards. |

|||

|

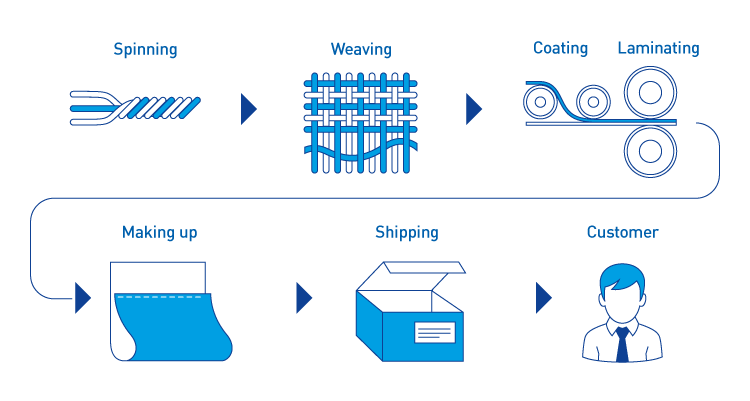

TRACEABILITY

Une We

have optimal traceability which provides, on an ongoing basis,

information throughout the manufacturing process. This allows our

processes to adapt quickly to change and offers greater transparency

and improved customer protection. |